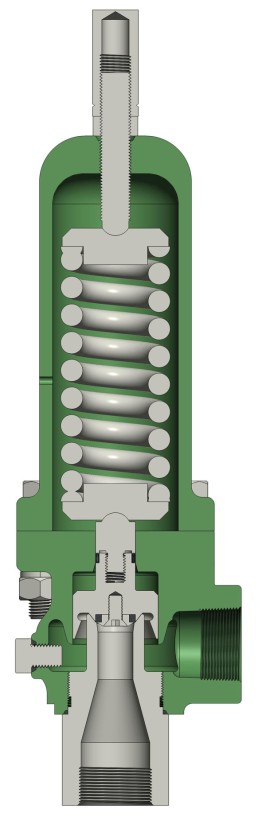

Features

|

APPLICATIONS

|

Service Envelope

Connection SizesCustom sizes available on request |

½” x ½” - 2” x 3” (13mm x 13mm - 50mm x 75 mm) |

Set Pressure RangesSee F88 Gas or Liquid Catalog for orifice specific ratings |

30 – 8,382 psig (2.1 - 578 barg) |

Temperature Ranges |

-423 to 400°F (-252 to 204°C) |

Orifice Area Range |

.065 – 1.689 in2 (41.9 – 1089 mm2) |

End ConnectionsCustom types available on request |

Threaded: NPT, SAE, MS33649/AS5202, AN 37° Flare Welded: ASME / DIN / API / SAE flanged, Grayloc Specialty: Swagelok® Tube / VCR, Threaded & Coned |

Materials of ConstructionCustom available for service or on request |

Carbon Steel, Stainless Steel, Monel, Hastelloy C / C22 / C276, Duplex 22% or 25% Cr |

Seat/Seal MaterialsCustom available for service or on request |

Seat Material (Plastic): Teflon®, Ekonol-filled PTFE, Kel-F (PCTFE), PI/PAI (Vespel®, Duratron®, or equal), PEEK Spindle Seal Material (Plastic): Spring-energized Teflon V-Seal |

Certifications & Compliance

- ASME Sec VIII Div. 1 (NB-18 Cert. No. 28044, 28055,28077, 28088, 28101, 28112, 28134, 28145)

- API 520 (Sizing & Selection of PRV’s) / API 527 (Seat tightness of PRV’s)

- Superior flow capability (KA factor) vs. equivalent API 526 orifice

- API 526 center-to-face dimensions available on most sizes

- NACE MR0175 H2S compliant materials available on request

- PED / CE (2014/68/EU) compliant on request

- Canadian CRN (all Provinces per CSA B51)

- ABS Product Design Assessment (Cert. No. 15-HS1393800-PDA)

- US Patent No. 7,513,270