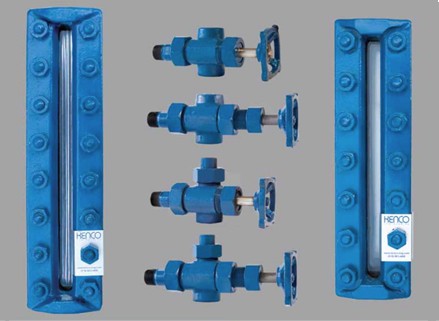

KENCO Flat Glass Gauges are used where direct visual observation of process fluids is required. These gauges are suitable for a wide range of applications with pressures up to 4000psig @ 100°F, and temperatures up to 750°F @ 2300psig. KENCO gauges are available in a wide variety of construction materials, connections and other options to meet most specifications.

1. Chamber - Center of the gauge, and is the part that primarily contains the process fluid. It is machined from bar stock. The gasket seat is recessed for lateral support, and easy positioning.

2. Glass - Provides the visual interface between the process fluid and the outside.

3. Cover - Protects the glass, and provides the compression surface for sealing the gauge. The cushion seat is surfaced for lateral support and easy positioning.

4. Gasket/Cushion - Provides for a seal between the chamber and glass (gasket), and protects the glass from mechanical stresses from the cover (cushion). For a given gauge, the gasket and cushion are normally the same material.

�5. Bolts/Studs/Nuts - Provides a uniform compression load to the gauge for pressure sealing.

REFLEX & TRANSPARENT STYLES

Reflex gauges have a single piece of glass, mounted on one side of the chamber. This piece of glass is flat on the outside, and has a series of prisms on the inside, facing the process fluid. When light strikes the portion of the glass covered by a liquid, the light is reflected from the back of the chamber. This area appears “black”. When light strikes the glass where no liquid is present, the prisms reflect the light directly out of the gauge. This area appears “silvery”. Reflex gauges provide an excellent way to measure clear, or dif ficult to see fluids.

�

The “silvery” / “black” interface is easy to see from several feet away. Transparent gauges have two pieces of glass on opposite sides of the chamber. Light enters the gauge from one side, and the level is viewed from the other. Transparent gauges are useful when the actual liquid characteristics need to be seen. They are also commonly used for liquid-liquid interfaces. Mica shields can be used in transparent gauges to protect the glass in steam environments. Kel-F shields should be used in corrosive environments.

WHY USE FLAT GLASS GAUGES

Flat Glass Gauges have been in use for over 100 years. They give you the ability to directly view the process fluid under temperature / pressure conditions that would render most other level technologies useless. Their construction is very robust, and reliable. They define the term “simple to use”. . . af ter installation, the only tool you will need is your eyes. Flat Glass Gauges are relatively inexpensive as compared to most other level technologies.